Precision Cold Forming

Unique tooling design enables near-net shape along with high dimensional accuracy and surface smoothness. Our cold forming techniques achieve tight tolerances, higher fatigue strength, lower weight and intricate shapes.

Hollow Axle Shaft

Engine Head Cap

Laced Wheel Spoke

Engine Bolt

Engine Stud Bolt

Material

- Carbon Steel

- High Alloy Steel

- Bearing Steel

- Stainless Steel

- Brass

- Aluminum

Finishes

- Zinc

- Nickel

- Trivalent Chromate

- Nickel Chrome

- Copper

- Phosphate

- Geomet

- LockPatch

Size Range

- Tubed Parts

8-30mm x L 50 – 1,000mm - Electrical Parts

3-12mm x L 5-30mm - Through Bolts

3-12mm x 1,000m - Custom by shape

Features & Benefits

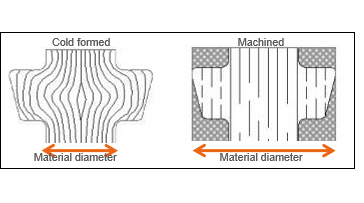

Maintains continuous fiber flow for increased part strength. Eliminates rough surface and potential chipping or fatigue cracks found in machined parts.

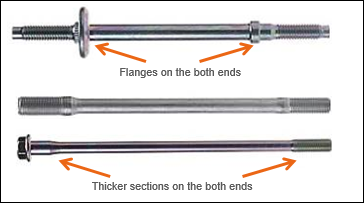

Open die enables flanges and/or thicker sections on both ends. The thicker section is higher strength and thinner center focuses on ductility. Suitable for applications with high tension and vibration.

RESOURCES