High Pressure Die Casting

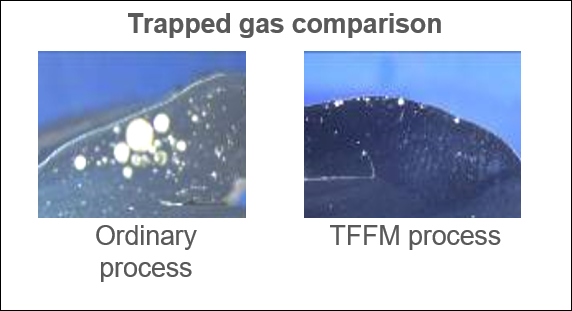

High speed injection (TFFM) combined with superior in-mold fluidity dramatically reduces trapped gas. Our unique process allows for hollow and weldable designs. Our capabilities allow us to achieve tight tolerances and thin wall thickness for less machining and weight reduction.

Sub-Frame

Lower Block

Inverter Case

Housing

Material

Aluminum

- Silafont36

- ADC10, 12, AZ91D, others

Magnesium

Zinc

Zinc

Finishes

- Chrome

- Anodized

- Paint

- Powder Coat

- Chemical Conversion

Features & Benefits

- Light Weight

- Magnesium Interior Frames/Housing

- Thin Wall Thickness to 1.0mm

- Hollow Design

- Weldable

- FSW- Friction Stir Welding

- Thermal Management

- Production Efficiencies

- Shortened Cycle Time

Equipment

- Up to 2500 ton

- Exceeds 20 machining centers

Process Capabilities

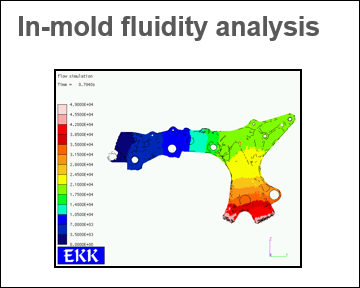

MAGMA mold flow analysis

CAE for in mold fluidity analysis for optimal design

CAE for in mold fluidity analysis for optimal design

TFFM (Transition Flow Filling Method) minimizes trapped gas

Controls gate speed and in-mold pressure