AdvanTech is a Sales, Market Development, Project Management and Distribution Organization.

AdvanTech International Inc. (ATI), was established in 1951 as a specialized international trading company has evolved into a global sales and market development organization. Driving product leadership, ATI partners with global leading manufacturers to deliver engineered product solutions through our strategically located operations.

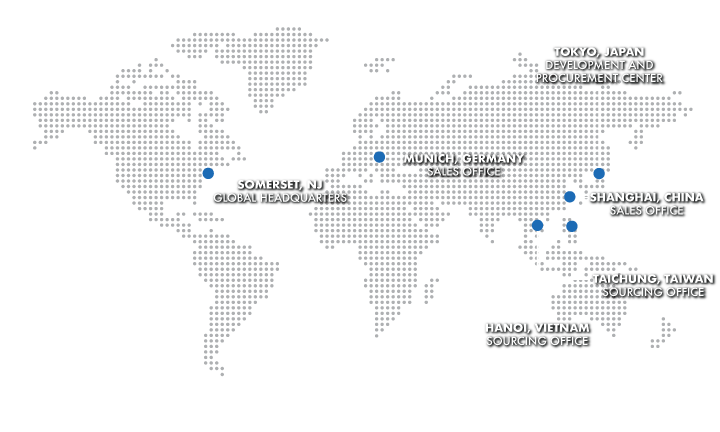

Global

Footprint

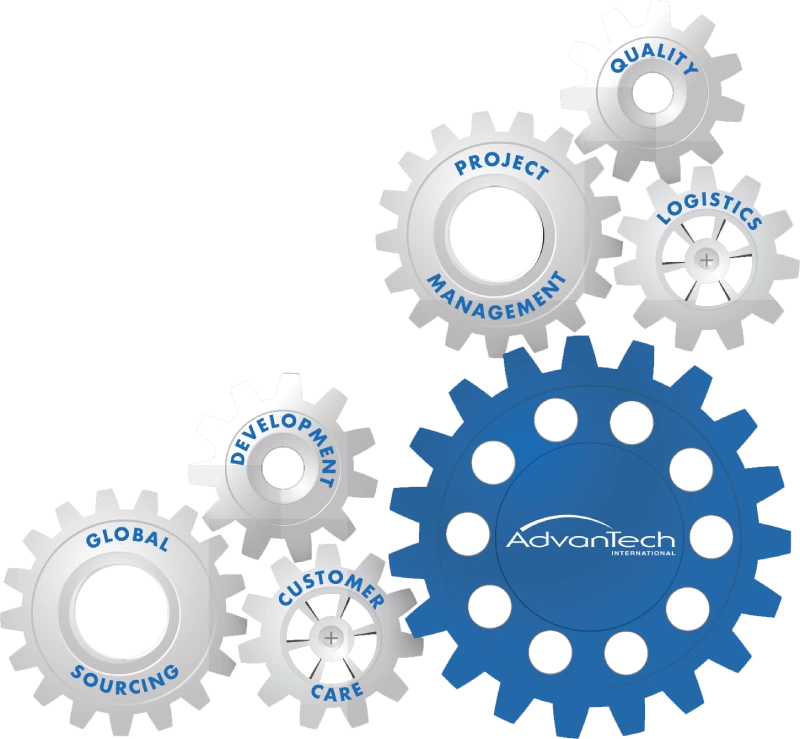

Core

Technologies

Value Added Services

Automotive

Applications

Motorcycle

Applications

Metal Forming

Technologies

Rotational Position Sensors

Automation

Applications

Automation

Components

Core Technologies:

- Precision Cold Forming

- Resolvers and Encoders

- High Pressure Aluminum Die Casting

- Press Forming/Precision Stamping

- Precision Machining

- Servo Motors

- Steel and Aluminum Forgings

- Precision Ball Screws & Actuators

- Gyroscopes and Inertial Measurement Units (IMU’s)

- Motorcycle Rims

- Metal Formed Thermal Management Components

- High Pressure Magnesium Diecasting

Value Added Services

Project Management

- Intercontinental program coordination with strategically located support

- AIAG and all International Major OEM & Tier 1 Standards

- Tier 1 Accountability

Commercial

- Contract Negotiation

- Global Currency Management and Transactions

- Incoterm Flexibility

- Continuous Improvement Management

Quality

- APQP Support

- Change Management

- ISO9001:2015 Certified

- Supplier Base IATF-16949

- 8D Non-Conformance Resolution

- Sorting, Containment, Inspection

- MMOG Compliant

Technical Support

- Application Engineering

- Multi-lingual Staff

- Global Business Culture Mediation

- Drawing Management

Development

- Global Sourcing

- Market Research

- Product Introductions

- Global Marketing Expertise

Supply Chain Logistics

- Global JIT Delivery

- Local Warehousing

- International Packaging

- Consolidated Freight Efficiency

- Shipping to Operational Requirements

- Repack and Labeling/Bar Coding

Validation

- Product Planning

- Management

- Laboratory Sourcing

Production Support

- Capacity Planning

- Material/Inventory Management

- Life Cycle Planning

Automotive Applications

Connecting unique component technology to the automotive industry through our global footprint

Metal Forming Technologies

- Precision Cold Forming

- Weldable High Pressure Aluminum Die Cast

- Press Forming & Precision Stamping

- Steel & Aluminum Forging

- Precision Machining

- Thermal Management Components

Rotational Position Sensors

- Variable Reluctance Resolvers

- Inertial Measurement Units (IMU’s)

Automotive Chain

- Engine Timing Systems

Motorcycle Applications

Connecting unique component technology to the motorcycle industry through our global footprint

Metal Forming Technologies

- Precision Cold Forming

- Weldable High Pressure Aluminum Die Cast

- Press Forming & Precision Stamping

- Steel & Aluminum Forging

- Precision Machining

Rotational Position Sensors

- Variable Reluctance Resolvers

- Inertial Measurement Units (IMU’s)

- Gyroscopes

Motorcycle Wheels

- Extruded Aluminum & Steel

- Aluminum Cast

Metal Forming Technologies

Precision Cold Forming

- Process Benefits

- High Degree of Processing Accuracy

- Tight Tolerances

- Intricate Shape

- Weight Reduction

- Reduction of Manufacturing Steps / Secondary Machining

- Materials

- Bearing Steel

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Finishes

- Trivalent Chromate

- Zinc

- Nickel

- Nickel Chrome

- Copper

- Phosphate

- Geomet

- Lock Patch / Sealer

High Pressure Diecasting

- Process Benefits

- Thin Wall Thickness to 1.0mm

- Hollow Design

- Weldable

- Friction Stir Welding (FSW)

- Weight Reduction

- Production Efficiencies / Decreased Cycle Time

- Materials

- Silafont36

- ADC1 8, 10, 12

- Magnesium

- Zinc

- Finishes

- Chrome

- Anodized

- Powder Coat

- Paint

Aluminum / Steel Extruded Rims & Cast Wheels

- Extruded Rims

- Material – Aluminum – 7050 Equivalent, 6061, 6062, 6063 & Steel

- Finishes – Chrome, Anodize, Paint, Laser Etching

- Features – Multiple Contours, Multiple Widths, Tube, Tubeless

- Cast Wheels

- Durable designs for rigorous applications

- Weight Reduction

- Custom Designs

- Friction Stir Welding

- Complex materials blend together becoming a single unit

- Minimize deformation & maintain mechanical properties of base material

- Reduction in pinholes, porosity and air leakage

- Paint

Precision Machining

- Process Benefits

- 5 Axis Machining

- Precision Tolerance up to 5 microns

- Machining Capacity – Max outer diameter up to 150mm, Max length to 1800mm

- Materials

- Aluminum Alloy, Steel, Copper, Titanium

- Finishes

- Zinc, Black Zinc, Chrome, Anodize, Sealant

Press Forming / Precision Stamping

- Process Benefits

- Shaping of teeth by one shot (no rolling or transfer process)

- Stamping process improves accuracy of gear/shear droop is minimized

- Improvement to mechanical properties

- Weight Reduction

- Applications

- Suspension, Power Steering, Engine Systems, Brake Systems

Thermal Management

- Battery Cooling Plate

- Unique Joining Technologies

- Fiber Laser Welding

- Specially Developed Adhesive

- Multiple Material Options

- Thin Wall Thickness

- Thermal Mapping / Simulation

- Large Footprint Capability

- Integrated Circuits

- Unique Joining Technologies

- Heat Sinks

- Skived Micro Finned Heat Sinks

- Precision Stamped Heat Sinks

- Unique Shapes / Small Size Capability

- Improved Surface Area

- Superior Thermal Conductivity

- Potential for direct mount to PCB

- Copper / Aluminum

Rotational Position Sensors

Singlsyn Speed & Position Sensors

- Rugged Variable Reluctance Design

- Absolute Signal

- Extremely Thin Axially

- Multi-Speed Options: 1x ~ 15x +

- Sizes from 11mm – 285mm O.D. +

- Wide Temperature Range: – 40° C ~ + 150° C

- Robust for Harsh Environments

- Vibration: 196 m/sec2 (20G)

- Shock: 980 m/sec2 (100G)

- Humidity: 90% RH +

- High Rotational Speed: 30,000 rpm

- Easily Customized for Shape or Electrical Connection

- Low Cost Design

Resolver To Digital R/d Convertor Ic

- Digital Tracking System, Analog to Digital Output

- Low Cost, Small Size

- High Speed – 12bit

- Operating Temperature: -40 to +125 Deg C

Gyroscopes

- MEMS Gyroscopes

- Compact Design

- Low Cost

- High Accuracy: 5 Deg / Hour

- Waterproof

- iFOG Gyroscopes

- High Accuracy: 0.1Deg/Hour

- Level 5 Autonomous Driving

- Unique Fiber Optic Winding Technology = Low Cost

- Closed Loop

- Inertial Measurement Units (IMU)

- High Accuracy / Attitude Angle < 0.1deg

- IP65

- Kalman Filter & GNSS Dead Reckoning Type

- iFOG/MEMS Combined Inertial Measurement Units

- Sensor Fusion for Level 5 Fully Autonomous Driving

- Improved Dead Reckoning: 0.1Deg/Hour

- Attitude: 0.1 Degree

Automation Applications

Connecting unique component technology to the automation industry through our global footprint

Ac/dc Servo Motors & Controllers

- Wafer Handling Robots

- Heavy Duty Industrial – Welding Robots

- Inspection Equipment

- Machine Tools – X/Y/Z Axes

- Pick/Place Automation & Robots

- X/Y Tables

- Medical Robots

- Biomedical & Life Science Automation

Precision Ball Screws, Actuators & Linear Guides

- Wafer Handling Robots

- Machine Tool – Lathes, Grinders

- Flat Panel Screen Equipment

- Testing & Inspection Machinery

- X/Y Tables

- Exoskeleton & Medical Robots

Rotary Encoders & Brushless Resolvers

- Motor Speed & Position Feedback

- Length Measurement

- Positioning

- Elevator Door Control

- Metering Pumps

- Tension Control

Inertial Measurement Units (Imu’s) & Gyroscopes

- Mobile Robots

- Self-guided Vehicles

- Autonomous Robots

- Autonomous or Self-driving Vehicles

- Stabilizing & Mapping Systems

- Automated Material Handling

- Agricultural, Construction & Mining Vehicles

Automation Components

Servo Motors/drivers/controllers

- High Performance & Low Cogging

- 3 W to 15 kW

- Very Compact

- Low Inertia

- Feedback Options

- Absolute Encoder up to 25bits

- Brushless Resolver

- Incremental Encoder 12,000 C/T +

Precision Ball Screws & Actuators

- Ball Screws

- Precision Ground & Rolled to C0 Accuracy

- High Load – High Speed – Quiet

- Wide Lead Range – 1mm to 50mm

- Diameter Size Range – 6mm to 125mm

- Ball Screw Actuators

- High Accuracy & Rigidity

- Leads from 1 to 20mm

- Various Mounting Designs and Sensor Options

Rotary Encoders

- Incremental

- Hollow Shaft & Shaft Designs

- Up to 12,000CT

- Absolute

- 11bit to 25bit Resolution

- Single & Multi-turn

- Magnetic Type

- Extremely Rugged

- Vibration Resistant

- Absolute, High Resolution

Brushless Resolvers

- Rugged Design

- High Accuracy Wound Rotor Type

- Variable Reluctance Type

- -55 to +155 Degrees C

- Vibration & Shock Resistant

- Various Mounting Configurations

- 6mm to 100mm Shaft Sizes (rotor bore)